Discover the very best Practices for Effective Foam Control in Industrial Applications

Discover the very best Practices for Effective Foam Control in Industrial Applications

Blog Article

Comprehending the Significance of Foam Control in Industrial Processes

In industrial procedures, foam control is typically a forgotten yet important element that straight influences operational efficiency and product stability. The existence of extreme foam can cause considerable obstacles, including disrupted blending and diminished reaction kinetics, which might eventually influence product top quality across different industries such as drugs and food production. Recognizing the subtleties of foam monitoring, consisting of potential improvements and effective approaches, increases vital inquiries regarding finest practices and future developments. What are the implications for industries making every effort for boosted productivity and compliance?

The Function of Foam in Market

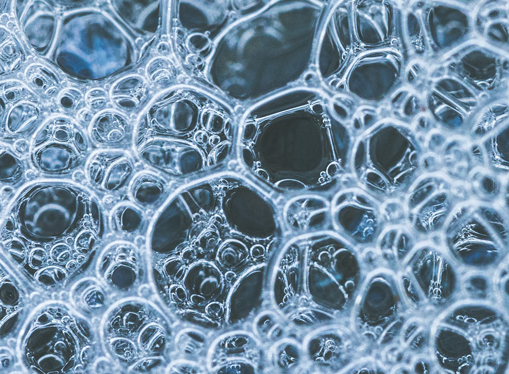

Foam plays a substantial role in numerous commercial procedures, influencing both effectiveness and product quality. In markets such as food and beverage, drugs, and petrochemicals, foam can serve both helpful and damaging purposes. For instance, in the food market, foam stabilization is critical during procedures like light whipping cream or generating beer, where the high quality of foam straight influences consumer understanding and item characteristics.

In chemical manufacturing, foam can act as a barrier, stopping the proper mixing of reagents, which can result in insufficient responses and suboptimal yields. On the other hand, in processes like flotation protection in mineral handling, foam is utilized to separate beneficial minerals from waste material, improving recuperation rates.

Furthermore, in wastewater therapy, foam development can show the existence of natural issue, offering as a crucial parameter for procedure tracking. The ability to regulate foam is important for preserving process security and enhancing operational expenses. Recognizing the duty of foam in industrial applications permits drivers and designers to carry out reliable foam monitoring techniques, guaranteeing that foam contributes favorably to general procedure efficiency while lessening its prospective drawbacks.

Usual Obstacles of Foam Development

Lots of industries deal with significant obstacles because of the unintentional formation of foam during different procedures. Foam can interfere with the efficiency of operations, bring about enhanced downtime and greater operational prices. In fields such as pharmaceuticals, food and beverage, and wastewater therapy, foam can hinder blending, lower product return, and complicate splitting up processes.

Additionally, foam can produce security hazards by obstructing clear exposure, which is important in settings where specific dimensions and monitoring are needed. The visibility of foam can also cause equipment damages, as extreme pressure build-up may occur in tanks and activators.

Additionally, the requirement for regular intervention to manage foam can divert sources and labor, eventually impacting efficiency. Environmental policies present one more difficulty, as excessive foam can cause non-compliance issues in effluent discharge, necessitating additional therapy procedures.

Influence On Item High Quality

In chemical manufacturing, foam can hinder reaction kinetics by restricting gas-liquid contact, causing insufficient reactions and lower yields. This not only influences the effectiveness of manufacturing however can additionally cause ineffective end items that do not fulfill regulative criteria or consumer specifications.

Additionally, in drugs, foam development throughout solution processes can introduce air bubbles right into sensitive compounds, compromising medicine effectiveness and stability. Furthermore, foam can trigger operational problems such as overflow and tools malfunctions, raising downtime and upkeep expenses, even more affecting item quality and consistency.

Techniques for Effective Foam Control

Addressing the difficulties posed by foam is vital for maintaining item top quality throughout various commercial sectors. Effective foam control approaches are necessary to mitigate the unfavorable results of foam formation, which can interrupt operations and compromise item honesty.

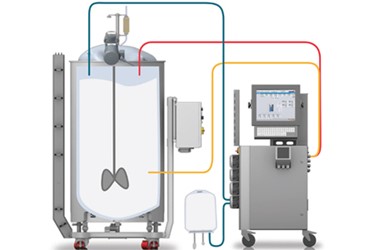

One of the primary approaches entails the option and application of suitable antifoaming agents. These agents are designed to decrease surface tension and inhibit bubble formation, and their efficiency can vary based upon the specific process conditions. Routine monitoring of foam levels is crucial to guarantee timely treatment, enabling operators to use antifoaming representatives prior to foam comes to be a significant problem.

Additionally, maximizing procedure specifications such as temperature and anxiety can play an essential duty in foam management. Minimizing frustration strength or readjusting feed prices can reduce foam generation. Executing mechanical foam control gadgets, such as foam breakers or defoamers, can also provide reliable services for high-foaming applications.

Educating workers on foam monitoring methods and the significance of keeping ideal operating problems further boosts foam control initiatives. Foam Control. By utilizing a combination of these methods, sectors can efficiently handle foam, making certain functional performance and keeping the quality of their products

Future Patterns in Foam Administration

Just how will innovations in technology shape the future of foam management in industrial my link processes? The combination of artificial intelligence (AI) and artificial intelligence will reinvent foam control methods, allowing real-time tracking and adaptive responses to foam development. These modern click here for more technologies can assess operational criteria and historic data to forecast foam actions, enabling for preemptive steps that enhance procedure effectiveness.

Furthermore, the development of innovative foam control agents, consisting of environmentally friendly and bio-based choices, is obtaining traction. These technologies not only minimize foam but additionally align with sustainability goals, lowering the ecological impact of commercial operations.

Automation will certainly additionally play an important duty, as automated foam control systems can enhance the dose of defoamers based upon real-time measurements, lessening waste and boosting effectiveness.

Moreover, the fostering of IoT (Net of Points) gadgets will help with seamless communication between tools and foam control systems, ensuring a holistic method to foam administration. (Foam Control)

Verdict

Finally, efficient foam control is essential for optimizing industrial processes across different fields. The challenges positioned by foam formation can substantially influence item top quality and functional effectiveness. Executing tactical foam administration strategies, consisting of making use of antifoaming agents and procedure optimization, reduces these difficulties. As markets remain to evolve, recurring developments in foam control technologies will certainly further boost productivity and sustainability, making sure compliance with ecological policies while keeping the integrity of items.

In the food market, foam stabilization is essential during processes like whipping cream or generating beer, where the high quality of foam directly impacts consumer perception and product characteristics.

Understanding the duty of foam in commercial applications allows drivers and engineers to implement reliable foam monitoring techniques, guaranteeing that foam adds favorably to overall process performance while minimizing its potential disadvantages.

Routine monitoring of foam degrees is important to make certain timely treatment, enabling drivers to apply antifoaming representatives before foam comes to be a considerable issue.

Executing mechanical foam control devices, such as foam breakers or defoamers, can likewise supply effective services for high-foaming applications.

The assimilation of synthetic knowledge (AI) and equipment discovering will certainly change foam control strategies, allowing real-time tracking and adaptive reactions to foam development.

Report this page